Sustainability

EAF vs.

Blast Furnace

Steel Dynamics steel production is 100% EAF

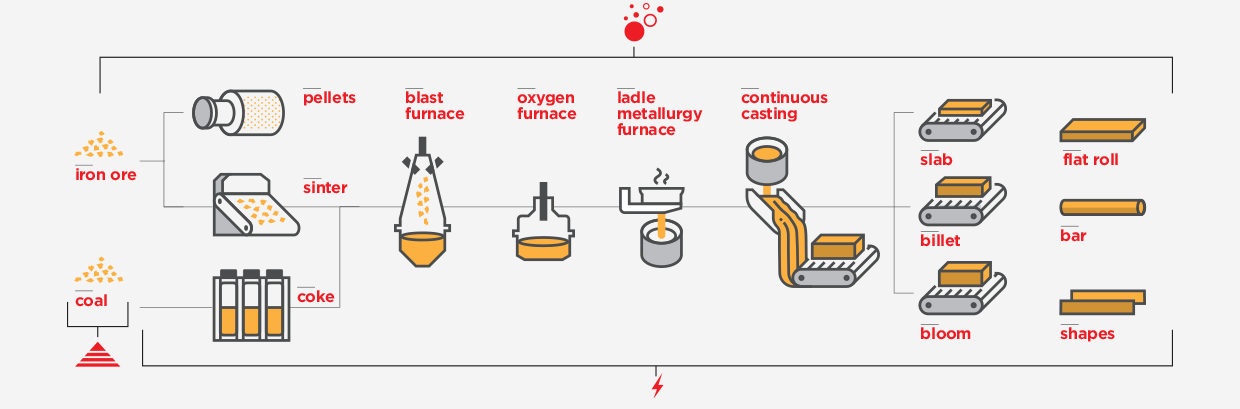

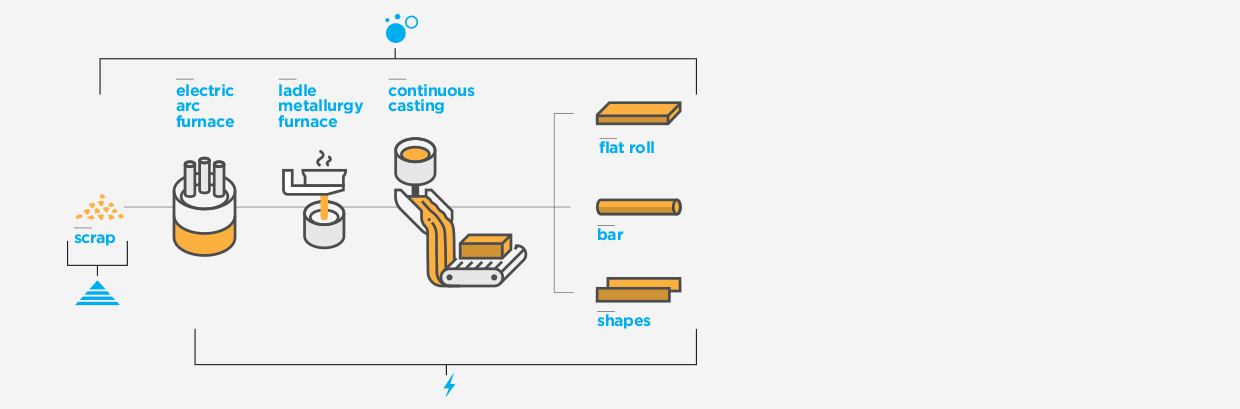

We believe the single most impactful decision a steel consumer can make in order to support greenhouse gas (GHG) emission reduction is to understand the differences between EAF and basic oxygen or blast furnace steelmaking technologies and related supply chain environmental impacts — and then, source their steel needs accordingly. EAF steelmaking technology generates a mere fraction of the carbon emissions produced and energy intensity required by traditional blast furnace steelmaking technology.

Eaf technology

Fewer natural resources required drives lower emissions, energy, wastes and water usage

Raw Materials

Steel is the most recycled material in the world.¹ Our EAF steel mills use recycled ferrous, or steel scrap, as the single-largest raw material input in the production of new finished steel products. In 2019, 84% of the material used in our furnaces to produce steel at our six EAF steel mills was recycled ferrous scrap and internally generated iron substitutes (in contrast to traditional blast furnace steelmaking, where the proportion of recycled ferrous scrap has been between 25% to 35%).

Eaf technology

Over 8 times lower emissions per ton versus average U.S. blast furnaces²

Emissions

Using EAF steelmaking technology, we produce substantially fewer emissions than produced from traditional blast furnace technology which creates significant air emissions through the conversion of iron ore, coke and coal into steel. Our steel mills’ GHG emissions are 89% lower per metric ton than the industry average of our U.S. blast furnace peers.²

Eaf technology

Our steel mills energy usage per metric ton is 75% less than world steel averages¹

Energy

By connecting the casting and rolling processes in our flat roll mills, we roll slabs into steel coils while the steel is still hot, requiring significantly less energy compared to traditional blast furnace technology, which typically requires reheating slabs before rolling. Our EAF operations energy intensity was 75% less than the average steel operations worldwide, when compared to the World Steel Association.¹

¹World Steel Association (WSA).

² Based on Scope 1 CO₂ equivalent emissions reported to the U.S. EPA.